Vertical Farming: A Look at Why it Could be theFuture of Food and How it is Done

- mcclements

- Nov 19, 2020

- 10 min read

Written by Tyler Bechtel & Megan Brockelbank

Photo Source: https://logisticsviewpoints.com/2020/01/29/vertical-farming/

Vertical farming could play a key role in food production in the

future due to the increased need to produce more food to feed the

growing global population. It is projected that the world population will

grow well over 9 billion by the year 2050. That added pressure and the

impending climate crisis we face we will have to more than double our

current food supply. In order to do this we will need to get creative

because currently most of the world’s arable land is already in production

or has been developed. Thinking sustainably, with most (around 70%

according to the UN) of the world’s population projected to reside in

urban areas by 2050, it would make the most sense to grow a portion of

the food in these urban centers. This will help to boost food security, food

sovereignty and increase sustainability by reducing food miles.

Currently the way we produce food is generally unsustainable and

energy intensive using an exorbitant amount of fossil fuels and water.

Agriculture uses about 70% of all the freshwater today. With climate

change and an increasing population there will likely be a big supply and

demand issue in the future as freshwater stocks begin to deplete due to

drought and the demand for food production and consumption continues

to rise exponentially. To avoid societal breakdown that water scarcity will

bring we will need to reconsider how to produce our food with much less

water. Vertical farming could solve this problem as it uses up to 90% less

water than traditional farming methods.

Food production is responsible for 17% of all the fossil fuel

consumption in the US alone and it is estimated that the average U.S. farm

uses a total of 3 calories of fossil fuel energy to produce each calorie of

food energy. This grossly inefficient use of fossil fuels in food production

is extremely unsustainable and comes largely from the way we industrially

farm our staple crops. Much of the fossil fuel consumption is used to

power large farm machinery, to make and transport chemical fertilizers

and pesticides, to process foods, to transport and refrigerate food, and to

produce food packaging materials. In order to fight climate change we

need to reduce this dependence and consumption of fossil fuels greatly.

Vertical farming, though energy intensive now, could help to reduce fossil

fuel usage in the future by reducing food miles by growing and selling

food produced locally in urban markets. Farming vertically would limit

fossil fuel consumption by not using big machinery over acres of land and

by eliminating the need for pesticides and herbicides due to the indoor

growing environment vertical farming provides.

Furthermore current agricultural methods use an increasingly large

amount of land to produce our food. Historically we would just clear more

land to make room for food production, however we need to keep our

forests in place in order to combat climate change, and a growing number

of parcels on arable land are being bought and developed for other

purposes leaving little arable land left to farm. We have already cleared

land that would amount to roughly the size of South America just to grow

crops and another amount of land roughly the size or Africa to raise

livestock to provide our current population enough food. Most of our

farm lands are also losing their top soils at an alarming rate due to tilling

and other agricultural practices making more of our land unsuitable for

agriculture in the future. This and the effects of climate change over the

last 40 years have contributed to the loss of ⅓ of all the arable land

globally. (4) There will not be enough land to continue to farm the way we

traditionally do and because vertical farming uses much less space and

does not require soil or an abundance of land and acreage to grow our

food it may be our only option to produce enough food to feed our ever

growing population in the future.

Standard farming practices grow less per meter squared than

vertical farming. Looking at lettuce production we can see that with

standard farming practices we would only produce 3.9 Kg of lettuce per

meter squared and would require 1,000 liters of water throughout the

growing season and then would likely travel anywhere between 1,500 and

2,000 miles before arriving at a grocery store or restaurant.

Whereas vertical farming could produce 80-120 Kg of lettuce per

meter squared while using 5 liters of water or less and travel far less as

vertical farms are often located much closer to the final destination

equating to a total of only 43 miles traveled. The close proximity to the

target market would greatly reduce the carbon footprint of the food, as

well as drastically reduce water consumption to provide more food per

square meter and can also be done year round in climates where they

typically would not be able to grow certain crops year round.

Vertical farming could also increase food security and food

sovereignty in many cities suffering from food deserts and food access

issues. Not only would more food be grown per square meter but more

food would be grown locally in low income neighborhoods where women

and people of color suffer most from food insecurity. Having vertical

farms could help to alleviate some of the food accessibility issues by not

only having more food available but also by potentially revitalizing

communities suffering economically by providing jobs which in turn would

increase food security and sovereignty.

While vertical farming has many pluses it also has a few minuses as

well. It can be very energy consuming and has huge start up costs that

may prohibit it’s adoption. Growing indoors requires the use of artificial

lighting and while lighting technology is increasingly producing more and

more energy efficient and longer lifespan bulbs a vertical farm would still

use a substantial amount of energy that currently comes from fossil fuels

which, as we know, contributes to climate change. If vertical farms

incorporated renewable energy sources though this would be a non-issue.

Companies could install solar panels or small wind turbines to help offset

the energy consumption from the lights and could potentially collect and

store rainwater off of their facility as well to make their vertical farm more

sustainable. Though that may be cost prohibitive for many operations

especially those just starting out.

There are four main components to the implementation of vertical

farming: facility layout, lighting, control and monitoring of nutrients and

conditions, and power supply. We will discuss each of these components in

detail along with the challenges that they may present.

Physical structure and layout : The main objective of vertical farming is to

increase crop yield and production per acre. This is achieved by growing

plants on a stacked, vertical plane as opposed to the one-dimensional

horizontal plane used in traditional agriculture. The structure and design

of vertical growth chambers can vary significantly based on the farm’s

desired features. In some cases, growth chambers are built similarly to a

glass greenhouse so that they can utilize a combination of natural

sunlight and artificial LED light. While this design is great because it

reduces energy consumption, it should be noted that this design cannot

be used just anywhere due to climate or spatial factors (i.e. nearby

buildings may cast shadows, cloudy regions). The main limitation in the

layout of these facilities is created by providing sufficient light to all

plants, despite them being stacked on top of each other. But there are

innovative ideas that are being explored to address this issue. One such

proposal is the use of “bamboo towers” shown below. The premise of this

design is to maximize the amount of sunlight reaching each level of the

tower.

To completely remove the dependence on sunlight, other operations

take place in large warehouses where each of the stacked plant trays are

lit with rows of LED lights.

Another structural element involves the water management system.

To maintain a sustainable model, many vertical farms have rainwater

collection tanks on the top level. Water management infrastructure is

often placed at the ground level of the vertical farm, where rainwater and

greywater is received, recycled, and redistributed to the plant beds.

The last structural consideration that must be made for the vertical

growth chambers is the HVAC management system. Plants need proper

ventilation and humidity control, which can be achieved through natural

air vents or fans. Heating and cooling systems will vary based on the

geographical location of the vertical farm and are often controlled by

data monitoring systems that track and regulate temperature and

humidity.

Nutrients and Growth conditions : The second element of vertical farming

is the use of various growth media and nutrient systems for optimal crop

production. The systems commonly used today include: hydroponics,

aquaponics, and aeroponics. Hydroponics is simply the growth of plants

in an aqueous nutrient medium without the need for soil. This method has

been employed for years by indoor marijuana growers, and is now being

utilized by some vertical farmers. This technique uses as much as 10 times

less water than field crops. Sky Greens, the world’s first commercial vertical

farming facility, uses a hydroponic irrigation system to support their 30ft

tall growth chamber located in Singapore. Aquaponics utilizes fish

farming to provide nutrients for the plants, while the plants in turn filter

the water for the fish. FarmedHere is a USDA-certified company based in

Chicago, IL that utilizes aquaponics by cultivating tilapia and using fish

effluent tanks to irrigate the plant beds. The simultaneous cultivation of

crops and fish and the symbiotic interaction between the two processes is

an attractive component of aquaponics. And finally, aeroponics is the use

of a nutrient mist for plant growth without the need for a physical

substrate. An industry example of this system is AeroFarms in Newark, NJ.

This leafy green producer uses a cloth medium in lieu of soil and

distributes an aeroponic mist to the root system. AeroFarm’s claims that

their production method uses 95% less water than traditional farming and

40% less than hydroponic systems.

Another benefit of indoor agriculture is the ability to have complete

control over the atmosphere to ensure optimal growth conditions for a

particular crop. As shown in the figure below, most commercial vertical

farms have a data monitoring system that is linked with sensors that

measure things like temperature, humidity, CO 2 , and light. Sensors and

data monitoring provides ultimate control of vital growth factors that are

unpredictable in nature and traditional agriculture. In contrast, outdoor

farming leaves crops susceptible to natural fluctuations in these growth

factors—in addition to things like drought, heavy wind, and agricultural

pests. Indoor farming and data monitoring also creates the possibility of

process automation. Manpower and labor costs are reduced significantly

by automating the lighting and fertigation of crops. When computers that

are synched with the plant data sensors reach a designated threshold, an

automated response can be programmed to alter the lighting or

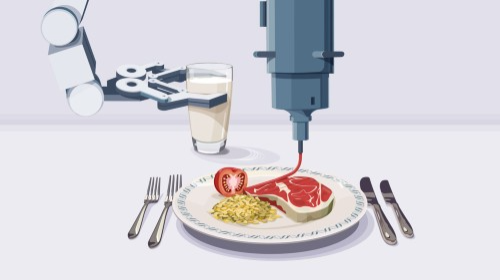

fertigation of a specific plant bed. In the future it is also possible that

tasks such as seed planting and transfer that could be tedious, or even

dangerous in the stacked plant towers, would then be completed by

robots.

Lighting: Artificial light is needed in most vertical farming facilities either

to supplement the natural sunlight or as the primary source of light

energy. In either case, LED lighting is the most energy efficient and

long-lasting artificial light option. Specialized growth lights are used that

have a pink appearance as they produce the exact wavelengths of light

that are necessary for rapid plant growth. Rotating plant beds are often

used in layouts that rely on natural light so that all of the plants receive a

uniform amount of sunlight. Without this rotation, the plant beds towards

the bottom of the stack wouldn’t receive ample sunlight and quickly die.

For example, Sky Greens facilities use a rotating plant system that rates

the plant troughs at 1 millimeter per second. Vertical Harvest, a 3-story

greenhouse operation in Wyoming, also uses a carousel-like design to

optimize light exposure.

Limitations: Ironically, vertical farming is very limited in its ability to

produce crops that grow tall vertical stalks. In nature and in traditional

farming, these plants depend on exposure to wind to strengthen their

stalks and subsequently provide the strength needed to support the

plant’s heavy fruit before harvest. In an indoor setting, all of the optimal

conditions of nutrients, water, light, and temperature are null if the plant

cannot support its own weight and snaps before harvest. For this reason,

leafy greens like spinach and lettuce are currently the only crops that are

being grown in commercial vertical farming facilities. Until new

approaches are developed, the potential for vertical farming to be applied

to a variety of crops is restricted by this inability to sustain vertical plant

growth.

Energy demands and power supply is also one of the major

limitations of vertical farming in its current configuration. Since the

objective of this novel form of agriculture is to provide a more sustainable

mode of production, it would be illogical for the energy consumption of

vertical farming to be comparable or even exceeding that of traditional

agriculture. But the simple fact is that plants need light. Indoor vertical

farming creates a dilemma where sunlight—a f ree , natural energy

source—is replaced by LED lights which require electricity, money, and

contribute to greenhouse gas emissions. This seems counterintuitive,

costly, and detrimental to the environment. To address this dilemma,

renewable energy sources are seen as the best alternative. As shown in

the bamboo tower figure above, the structure is powered by solar panels

and a wind turbine. Obviously, this would be an ideal situation because

the facility would be a truly sustainable model. But again, there are

limitations with this design. In addition to the substantial upfront cost of

solar panels and wind turbines, the effectiveness of the renewable energy

production would be largely dependent on geographical location and

weather patterns.

And lastly, vertical farming enables the possibility of producing fresh

vegetables in urban areas that are commonly devoid of fresh produce. As

shown in the “bamboo tower” above, the first floor of many proposed

vertical farms are designated for a grocery store or restaurant. This

enables a true farm-to-table process to take place even in an urban

environment. This is an appealing feature, however, it is not without

complications. The enormous upfront costs of vertical farming facilities

may be too much to even begin construction, especially within urban food

deserts that are often in lower-income neighborhoods. Also, the high cost

of the food produced by vertical farms will be a deterrent to customers.

Overall vertical farming could potentially be the way we meet the

demands of a growing population in the future if the constraints of high

cost and energy consumption are somehow reduced. While vertical farms

are not suitable for growing staple crops like corn, they could contribute a

diverse quantity of vegetables and herbs, particularly to urban

environments that are devoid of any form of food production and house

the majority of the global population. This would increase cities food

security and end the reliance on rural communities to produce their food.

Therefore increasing the sustainability and self reliance of the city.

Sources:

1. Baraniuk, C. (n.d.). How vertical farming reinvents agriculture. B BC . Retrieved from

https://www.bbc.com/future/article/20170405-how-vertical-farming-reinvents-agric

ulture

2. Beacham, A. M., Vickers, L. H., & Monaghan, J. M. (2019). Vertical farming: A summary

of approaches to growing skywards. The Journal of Horticultural Science &

Biotechnology, 94(3), 277-283. doi:10.1080/14620316.2019.1574214

3. Beck, C. (2017, November 28). A beginner’s guide to vertical farming - Eco warrior

princess. Retrieved November 17, 2020, from Ecowarriorprincess.net website:

https://ecowarriorprincess.net/2017/11/a-beginners-guide-to-vertical-farming/

4. Benke, K., & Tomkins, B. (2017). Future food-production systems: vertical farming

and controlled-environment agriculture. Sustainability: Science, Practice and

Policy, 13(1), 13–26. https://doi.org/10.1080/15487733.2017.1394054

5. Desjardins, J., & Wood, T. (2016, July 4). Infographic: How vertical farming works.

Retrieved November 17, 2020, from Visualcapitalist.com website:

https://www.visualcapitalist.com/how-vertical-farming-works/

6. Kalantari, F., Mohd Tahir, O., Mahmoudi Lahijani, A., & Kalantari, S. (2017). A Review

of Vertical Farming Technology: A Guide for Implementation of Building Integrated

Agriculture in Cities. Advanced Engineering Forum, 24, 76–91.

https://doi.org/10.4028/www.scientific.net/aef.24.76

7. LeBlanc, R. (n.d.). What you should know about vertical farming. Retrieved

November 17, 2020, from Thebalancesmb.com website:

https://www.thebalancesmb.com/what-you-should-know-about-vertical-farming-41

44786

8. Mok, W. K., Tan, Y. X., & Chen, W. N. (2020). Technology innovations for food security

in singapore: A case study of future food systems for an increasingly natural

resource-scarce world. Trends in Food Science & Technology, 102, 155-168.

doi: https://doi-org.silk.library.umass.edu/10.1016/j.tifs.2020.06.013

9. Neale, K. C. (2020). Agriculture, fossil fuels and electricity. Mainstreaming solar

energy in small, tropical islands (1st ed., pp. 69-93) Routledge.

doi:10.4324/9780429346248-6 Retrieved from

https://www-taylorfrancis-com.silk.library.umass.edu/books/9780429346248/chapte

rs/10.4324/9780429346248-6

10. SharathKumar, M., Heuvelink, E., & Marcelis, L. F. M. (2020). Vertical Farming: Moving

from Genetic to Environmental Modification. In Trends in Plant Science (Vol. 25,

Issue 8, pp. 724–727). Elsevier Ltd. https://doi.org/10.1016/j.tplants.2020.05.012

11. Why vertical farming is the future of food. RealLifeLore2 (Director). (2020, May

17,).[Video/DVD] Retrieved from https://www.youtube.com/watch?v=IBleQycVanU

12. Indoor urban farms called wasteful, “pie in the sky.” (n.d.). Retrieved November 17,

2020, from Cornell.edu website:

https://news.cornell.edu/stories/2014/02/indoor-urban-farms-called-wasteful-pie-s

ky

13. Technology. (n.d.). Retrieved November 17, 2020, from Skygreens.com website:

https://www.skygreens.com/technology/

14. Vertical farming 2020 (the MEGA report). (n.d.). Retrieved November 17, 2020, from

Urbanvine.co website: https://www.urbanvine.co/blog/vertical-farming

15. Vertical Farming for the Future. (n.d.). Retrieved November 17, 2020, from Usda.gov

website: https://www.usda.gov/media/blog/2018/08/14/vertical-farming-future

Comments